Notice: This fireplace mantel will be available for viewing at our premises starting from December 15, 2025.

Let’s imagine that one of the thousand architects working for the Ferrero family (the richest in Italy) is looking for a fireplace for one of their thousand villas, and that it should meet the following criteria:

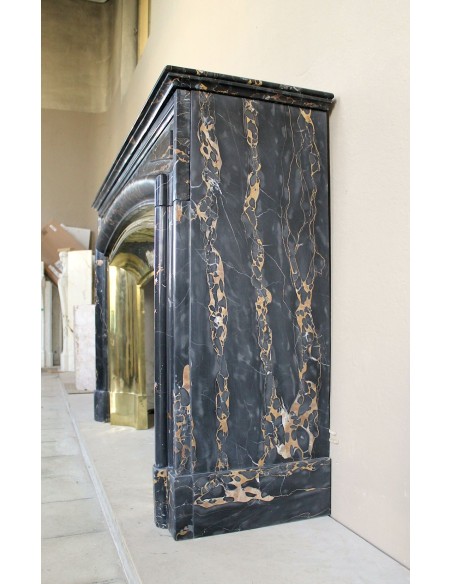

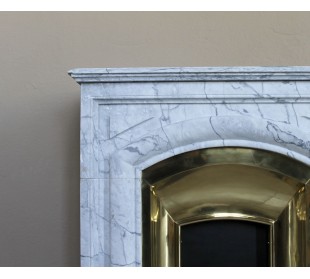

A) Big, powerful, about a metre and a half wide…

B) With strong yet soft lines, almost sensual, you know?

C) Fairly deep, to look more proportionate…

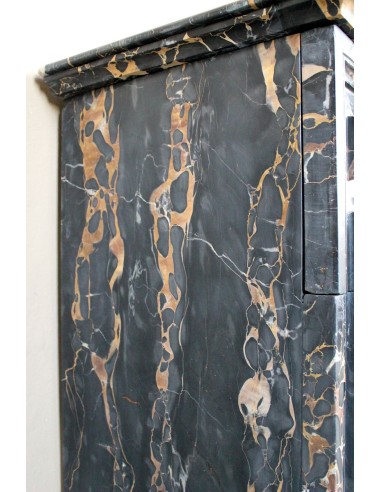

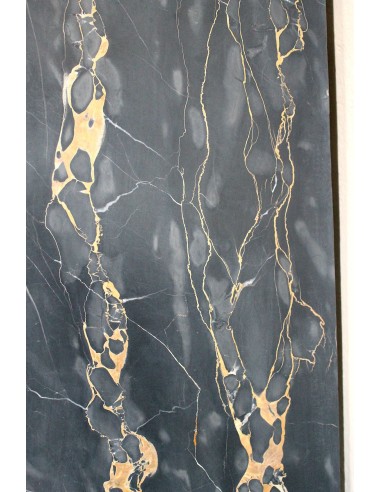

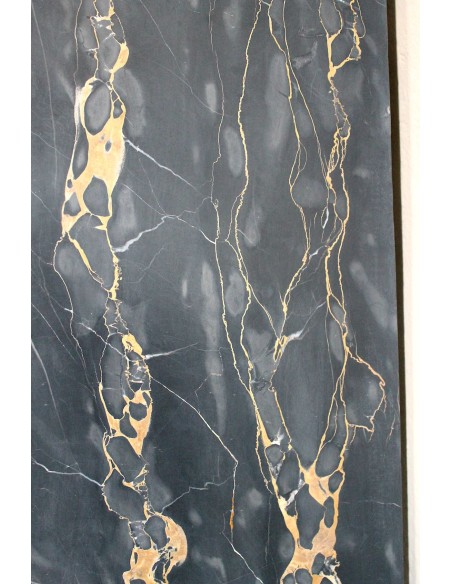

D) Carved in a refined and absolutely precious marble (PORTORO MARBLE IS THE MOST PRECIOUS IN THE WORLD)…

E) Oh, I almost forgot — WITH GOLD-COLOURED VEINING…

F) And of course: Absolutely complete with its original fireback, ABSOLUTELY GOLDEN AS WELL — WHICH, COINCIDENTALLY, IS MY CLIENTS’ FAVOURITE COLOUR...

G) Naturally, considering the importance of the client, the fireplace must be PERFECT...

Well, tell me — with all these demands, where else could this Nutella-loving architect possibly find such a BIJOU if not at Artis?! (Yes, I’m being cheeky and a little presumptuous — truth is, a fireplace like this comes through here only once in a blue moon. But this time, the stars aligned, and I hope you’ll forgive me for using it to show off the great variety we offer in our warehouse.)

Well then, if such an architect were to come my way with these requests, I’d answer like this:

“Would you believe it, dear architect — just two or three days ago, we completed the ‘maquillage’ on a stunning Louis XIV fireplace IN PERFECT CONDITION, CARVED IN THE ULTRA-PRECIOUS PORTORO MARBLE (THE QUARRY HAS BEEN EXHAUSTED FOR 50 YEARS NOW) AND — AS IF BY FATE — COMPLETE WITH A FIREBACK IN A CHARMING, GOLDEN... BRASS SHEET!!!”

Let me close this commentary with something I care deeply about and have never written on the site.

You should know that many clients think a brass fireback is less valuable than a cast iron one. It’s not so. A cast iron fireback is the result of a “quick” mould casting, while a brass fireback required days of precise labour — hammering brass sheets with wooden mallets over an anvil, periodically heating the brass in a charcoal forge to soften it.

All of the shaping was done gradually over days and days, with care and the kind of expertise only “old-school” blacksmiths had.

ITS ORIGIN DATES BACK TO BETWEEN 1840 AND 1860, AND ITS CONDITION IS FLAWLESS.